How to Use Cling Film Correctly in Commercial Kitchens?

Cling Film – A Silent Essential in Every Commercial Kitchen

In the whirlwind environment of a commercial kitchen, where speed, safety, and sanitation must coexist in perfect harmony, cling film emerges as one of the most essential, yet often overlooked tools. Whether it’s wrapping freshly prepped vegetables, preserving raw meat, or sealing leftovers for next-day service, cling film plays a silent but significant role in food protection and storage.

Despite its ubiquity, cling film is frequently misused in professional culinary environments. When used improperly, it can lead to cross-contamination, food spoilage, and even unnecessary plastic waste. This blog aims to guide kitchen professionals chefs, caterers, and food safety managers on how to use cling film correctly in a commercial setting, ensuring efficiency, hygiene, and sustainability.

Understanding the Basics of Cling Film

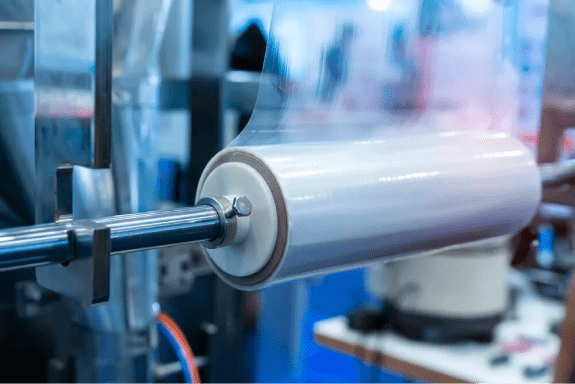

Cling film, also known as plastic wrap or food wrap, is a thin, flexible plastic material designed to seal food items tightly. It is typically made from polyvinyl chloride (PVC) or low-density polyethylene (LDPE), materials known for their excellent stretchability, moisture resistance, and transparency.

Its primary function is to create a protective barrier around food items. This prevents exposure to air, contaminants, and odors, thereby slowing down spoilage and preserving freshness. However, not all cling films are the same, and knowing which type to use and when is the first step toward correct usage in a commercial setting.

Key Functions of Cling Film in Professional Kitchens

In commercial kitchens, cling film performs multiple functions simultaneously. It protects food from airborne contaminants and pests, helps retain moisture in items prone to drying out, prevents flavor transfer between stored ingredients, and extends shelf life. Furthermore, it offers a quick, visible way to identify and date-stamp food in refrigeration units.

It also supports portion control and mise en place procedures by keeping pre-prepped items ready and safe for later use. For high-volume kitchens and institutions, this contributes significantly to efficiency and waste reduction. Understanding these functions helps ensure cling film is deployed purposefully rather than haphazardly.

Best Practices for Safe and Effective Usage

Using cling film correctly starts with a solid understanding of food safety and hygiene principles. First, always ensure that the film is food-grade and designed for use in foodservice operations. Do not use industrial-grade plastic film in the kitchen, as it may contain harmful chemicals not approved for food contact.

When wrapping food, make sure the film touches only clean surfaces—both the food item and the preparation area. Use separate rolls of cling film for different food types, especially when handling raw meat, seafood, and produce. This simple separation minimizes the risk of cross-contamination.

Moreover, label each wrapped item with a date and description before refrigerating or freezing. Even though cling film helps extend shelf life, it is not a substitute for proper FIFO (First-In, First-Out) practices.

Avoiding Common Mistakes

One of the most common mistakes made with cling film in commercial kitchens is failing to seal it properly. A loosely wrapped tray or bowl allows air to enter, defeating the purpose of using cling film in the first place. Stretch the film tautly over the item and press it down firmly to ensure a secure seal.

Another mistake is using cling film for hot items. Most cling films are not designed to withstand high temperatures and can melt or release harmful substances when in contact with hot food. Always allow food to cool before wrapping or use heat-resistant variants where necessary. Lastly, do not wrap food too tightly, especially delicate produce or soft desserts, as excessive pressure can crush or deform them. Proper wrapping should preserve both safety and presentation

Compatibility with Refrigeration and Freezing

Commercial kitchens rely heavily on cold storage, and cling film must be compatible with these environments. While most food-grade cling films are suitable for refrigeration, not all are freeze-safe. When freezing food, use cling film that remains flexible and durable at low temperatures. Ensure there is no trapped moisture inside the wrap, as this can lead to freezer burn or ice crystallization, which compromises the food’s texture and taste. When thawing, remove the cling film to allow even defrosting and prevent steam buildup, which could lead to soggy or overcooked portions.

Environmental Considerations

While cling film is a practical necessity in commercial kitchens, it also contributes to plastic waste if not used mindfully. Many establishments are moving towards biodegradable or compostable wraps, and some opt for reusable alternatives like silicone covers and food-safe fabric wraps for less demanding applications.

To minimize waste, use only as much film as necessary, and avoid double-wrapping unless absolutely required. Train staff on correct tearing techniques and storage practices for rolls to prevent unnecessary discards due to damage or contamination.

Implementing a waste tracking system in the kitchen can also help measure cling film consumption and identify opportunities for more sustainable practices without compromising food safety or operational efficiency.

The Importance of Quality and Supplier Choice

In a high-volume kitchen, the performance of cling film directly impacts food safety and productivity. Low-quality cling film tears easily, doesn’t seal properly, or becomes brittle in the fridge—leading to frustration, re-wrapping, and higher costs. Investing in premium cling wrap that is designed for commercial kitchens saves time, prevents waste, and reduces spoilage.

Choosing the right supplier ensures consistency in quality, supply chain reliability, and compliance with food safety standards. Commercial kitchens should partner with suppliers who understand the specific requirements of the foodservice industry and offer a range of wrap types suited for varied storage conditions.

Choosing the Right Cling Wrap Manufacturer in Singapore

If you’re operating within the foodservice industry, aligning with a dependable Cling Wrap Manufacturer in Singapore is essential for maintaining consistent performance and safety. Singapore-based manufacturers are known for adhering to high standards of hygiene and product integrity. Their proximity also ensures quicker delivery times and more agile supply chain responses critical advantages in an industry where timing and freshness are everything.

By partnering with a manufacturer that focuses on food-safe materials and commercial-grade quality, restaurants and catering businesses can reduce plastic waste, ensure safer storage, and improve kitchen workflow without constantly worrying about wrap failure.

The Role of a Trusted Cling Wrap Supplier in Singapore

More than just vendors, a reliable Cling Wrap Supplier in Singapore serves as an operational partner to many commercial kitchens. These suppliers not only provide the cling film itself but often offer advice on best practices, inventory management, and new sustainable alternatives. Working with experienced suppliers also ensures that kitchens have access to bulk solutions, custom sizes, and specialized wraps tailored for freezing, reheating, or odor containment.

Whether you operate a Michelin-starred restaurant or a hospital kitchen, having a local, responsive supplier helps keep costs predictable and inventory stocked, while also supporting compliance with Singapore’s strict food safety regulations.

Why Greenpacks Leads as a Cling Wrap Manufacturer and Supplier

Among the top names in sustainable food packaging, Greenpacks stands out as a premier Cling Wrap Manufacturer in Singapore and Cling Wrap Supplier in Singapore. With a commitment to quality, hygiene, and eco-responsibility, Greenpacks offers a wide range of food-safe cling wrap products tailored for commercial kitchen use.

Their cling film is engineered for optimal stretch, durability, and sealing performance. Greenpacks also offers biodegradable and eco-friendly options for kitchens striving to reduce their plastic footprint without compromising efficiency. Backed by strong logistics and customer service, Greenpacks is more than a supplier they are a strategic partner for modern foodservice operations.

Smart Wrapping Is Safe Wrapping

Cling film may be a small component in the daily rhythm of a commercial kitchen, but when used correctly, it contributes enormously to food safety, operational efficiency, and sustainability. From preventing contamination to improving shelf life, its benefits are wide-ranging provided it’s applied thoughtfully and supported by a quality product.

Partnering with a reputable Cling Wrap Manufacturer in Singapore or Cling Wrap Supplier in Singapore like Greenpacks ensures that your kitchen has access to durable, food-safe, and environmentally conscious cling wrap solutions. In an industry where margins are tight and standards are high, such a partnership can make all the difference in not just freshness, but also quality and trust.